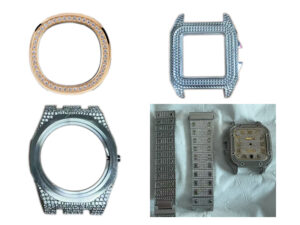

Today, I would like to brief the stainless steel tonneau shape watches process. The tonneau shape watches are different from circle stainless steel watches, adding dozens of pure machining time, additional not counting the weeks of preliminary preparations, such as the 60-80 different stamping operations required for the bezel, case lug, and back case.

The machine tooling process involves 8 days of adjusting the machines for the main case, 5 days for the case lug, and 5 days for the back case. Because the radian increases the difficulty of the process. Prior to this process, developing a methodology for carrying out this series of operations took 145 hours, the drawings for the tools 130 hours, and implementation 180 hours. Each case represents more than 215 separate machining operations.

After machining is completed, the watch case undergoes brushing and polishing, all executed by hand, followed by assembly with sapphire glass and sealants and preliminary water-resistance testing, before being disassembled and undergoing a final quality control. Only then will the movement be mounted within its subtle lines. All of these operations represent an additional a day of work.