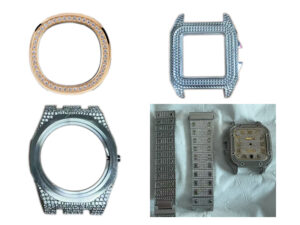

These are iced-colored bezels for mechanical watches. The inlay position, quantity, size, and shape of the purple stones are all arranged according to the customer’s design. The hole position of each stone is precisely calculated by the CNC machine, and there are claws to fix the stone when inlaid. This way of inlaid can be more solid. This is very different from the sticky stone process.

Our factory focuses on various types of high-end watch customization. Dive watches, Chronograph watches, Full Iced Out & Bust Down watches, etc.

Workers are finely polishing the steel bezel. Because before we assemble each part into a finished watch, each part must be inspected by QC staff for quality, and the next step can only be arranged after passing the pass. Therefore, workers must control the quality very well.