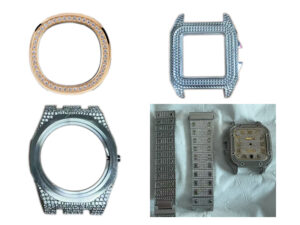

Case material of the stainless steel watch

Most wristwatch manufacturers divide the watch case material into precious metals (gold, platinum, rose gold) and special materials (carbon fiber, sapphire crystal, etc.). In general, the key to the price of the watch is the material. Therefore, the stainless steel watch is the most affordable among various materials.

Although they are called by a joint name: stainless steel, stainless steel materials can be divided into 304L, 316L stainless steel and 904L stainless steel. What are the differences between the two? We will introduce it in the following.

1. 304L stainless steel

304 stainless steel is a universal stainless steel material, which is also better in high temperature resistance. 304 stainless steel has excellent corrosion resistance and good resistance to intergranular corrosion. For the nitric acid, it was found in the experiment that the 304 stainless steel plate has strong corrosion resistance in the nitric acid with the concentration ≤65% below the boiling temperature. It also has good corrosion resistance to alkaline solutions and most organic and inorganic acids.

2. 316L stainless steel

The main components of 316L stainless steel are iron, chromium, nickel, and molybdenum. The density is close to iron. It has good corrosion resistance, and it will not affect the human skin. Therefore, in addition to being used to make watch cases, the use of a 316L stainless steel and bracelet is also very common.

The manufacturing process of 316L stainless steel is demanding. After the first casting, the metal will be re-melted into a vacuum container and purified to remove the impurities. It can be used by wrist watch manufacturers to produce watches only after confirming the quality by an electron microscope. Since 316L stainless steel is very hard, the subsequent processing and other processes are still a challenge, and the process is also difficult.

3. 904L stainless steel

Besides the 304L and 316L stainless steel watch, there is a 904L automatic stainless steel watches. 904L stainless steel is mainly used in chemical reactors, seawater treatment equipment, and other equipment in contact with highly corrosive substances. Therefore, its corrosion resistance is stronger than 304L and 316L. The difference is due to the elements that make up the alloy. 316L steel and 904L steel are almost the same, and they are mainly composed of nickel, chromium, and molybdenum. However, the proportions are different. In addition, 904L steel has a small amount of copper so that the corrosion resistance and wear resistance are stronger than 316L. Also, they do not have much difference in strength and hardness.

However, 904L steel requires difficult forging and high production costs. Few wristwatch manufacturers will choose it. Currently, 316L stainless steel is used more, because it is economical and more cost-effective.